This mindset is cemented throughout the supply chain, from the NextGen crushing plants to a planned conversion to autonomous haulage on MinRes’ private haul road and industry-leading transhippers ferrying iron ore to ocean going vessels 40km offshore.

But it’s at Ken’s Bore where an automated laboratory – the first of this type in the mining industry – is providing accurate, real-time data to help MinRes’ Mining and Technical Services (MTS) team make mine planning decisions to efficiently develop the project’s deposits.

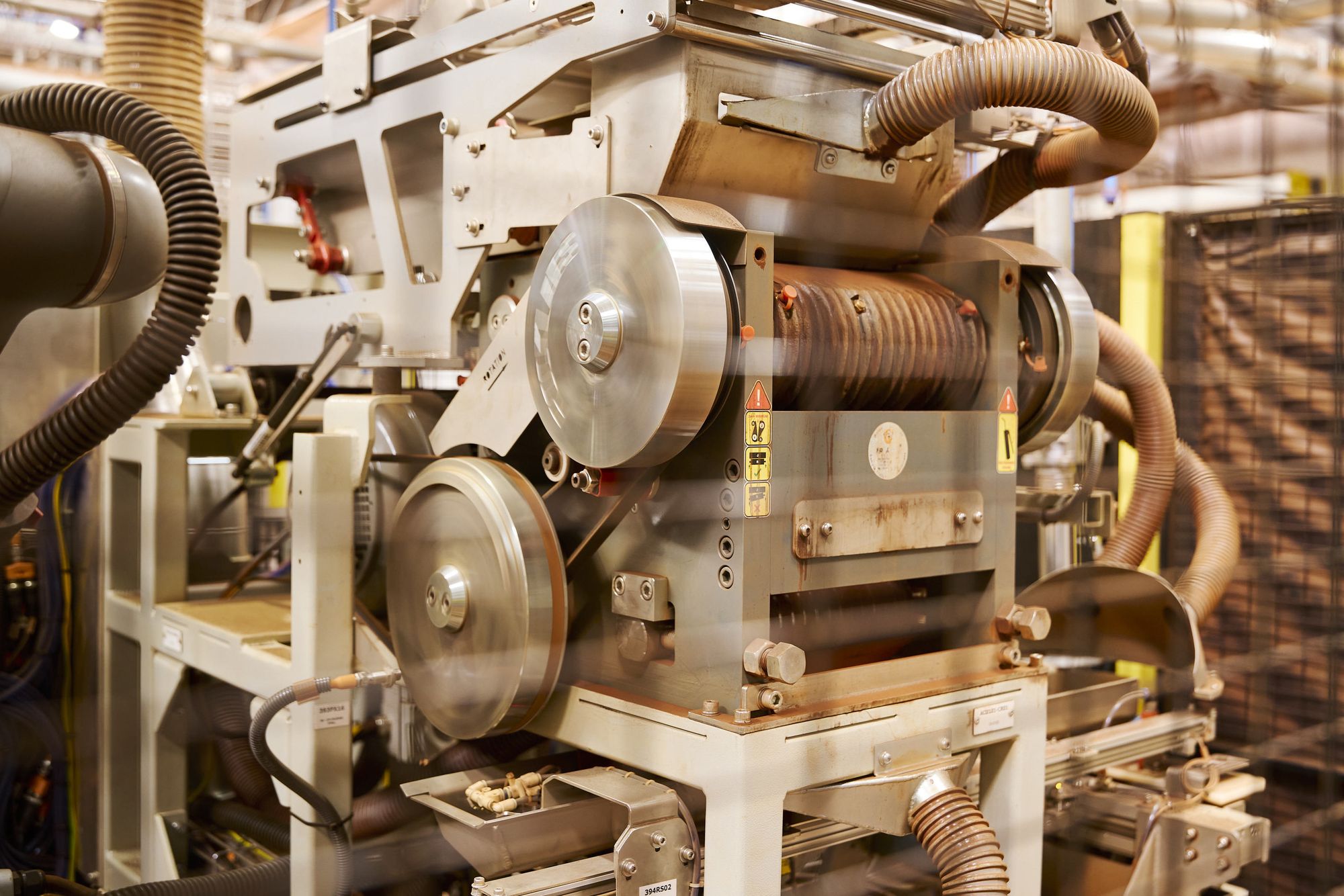

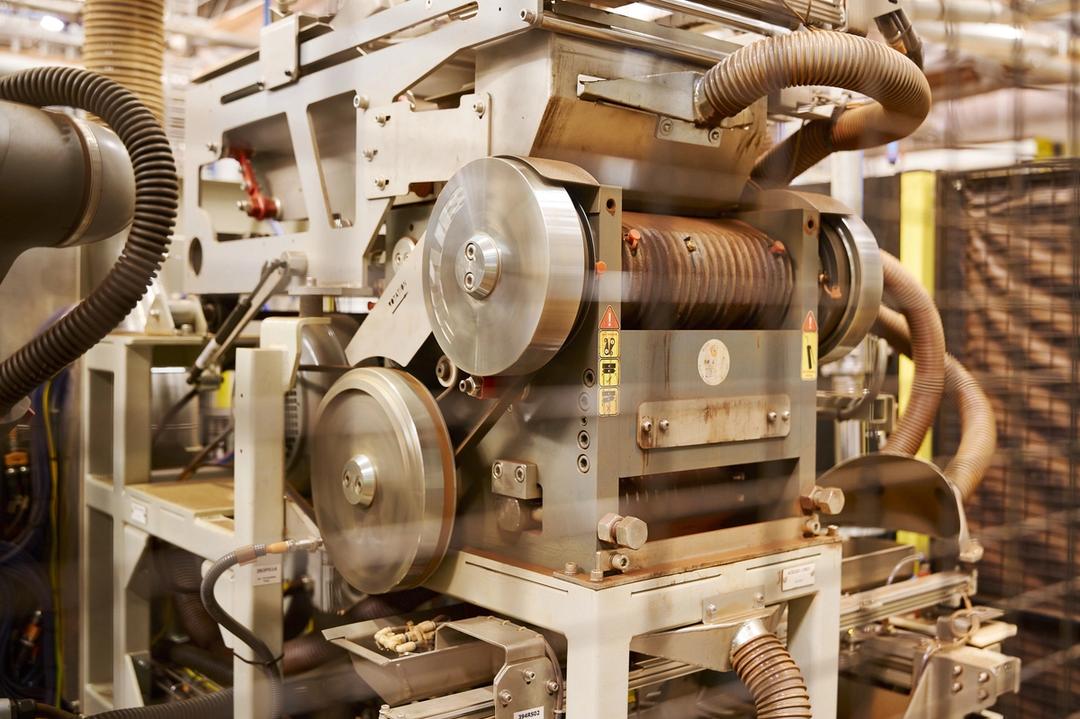

The Automated Modular Solution (AMS) Prep Line technology was developed and installed by industry-leader Rocklabs – a New Zealand-based business part of the international robotics and automation company, Scott Technology.

The AMS Prep Line technology uses a series of collaborative robots to easily take samples from the field, reduce their size and efficiently provide information to the project’s MTS team.

The technology has injected immediate benefits into the project, doubling sampling capacity to 500 per day and reducing several repetitive and manual processes.

Additionally, by completing the sampling process onsite, MinRes retains greater control and sees increased efficiencies, helping the business to make faster grade control changes in the mine when required.

Automated analysis

Following drilling activities in the field, samples are taken to the laboratory where the automated process begins.

Five-kilogram samples are bagged and tagged, with robotic arms transporting them to a crusher that reduces their size to 1kg – a process repeated 16 times per hour.

The samples are then transported down the line into a pulveriser mill, which self-cleans to ensure a very low level of contamination.

Now reduced to 100 grams, the samples are automatically dispensed into vials and loaded into crucibles ready for thermogravimetric analysis (TGA) and X-ray fluorescence (XRF) analysis – processes which provide critical information about iron ore grade level, as well as the presence of other elements.

Onslow Iron Manager Supply Chain Mike Dwyer said the technology was playing an important role in the project.

“With automation, you get reliability and repeatability and that’s one of the key factors that you want in the laboratory,” Mike said.

“One of the added benefits is that we’ve reduced the amount of manual handling that’s required by the lab technicians, which has led to greater throughput and quicker results.”

“This technology is playing a critical role in mine planning and the results are integral to ensuring we get the best out of more than 30 years' mine life at Onslow Iron,” he added.

“We were pleased to work alongside an industry leader like Rocklabs to deliver the technology for our laboratory – their products are proven and deliver accurate and timely results.”

Scott Technology CEO Mike Christman said the success of the Ken’s Bore laboratory was testament to the impact automation can have on mining operations.

“We’re proud to support MinRes with our turnkey end-to-end automated sample preparation system – it’s fast, reliable, and designed to deliver high-throughput, low contamination results that mine teams can trust,” Mike said.

“This project showcases what’s possible when industry leaders collaborate to push the boundaries of productivity and precision in mining.”

Supported by automation and with an expected mine life of more than 30 years, Onslow Iron is now ramping up production towards the project’s nameplate capacity of 35 million tonnes per year.

Read more about the Onslow Iron project.